Homepage » News » Achievements »

Innovative supported catalysts – driving industrial progress

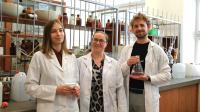

Ewa Iwanek, PhD, from the Faculty of Chemistry at Warsaw University of Technology, together with her thesis students, is developing highly active supported catalysts, where the active phase is deposited on high-surface-area oxide solid solutions. These supports are oxides (CeO₂, ZrO₂, and Al₂O₃) doped with trace amounts of foreign ions—a strategy that maintains the structure of the parent oxide while significantly enhancing its physicochemical properties.

Unlike high-temperature solid solutions commonly used in fuel cells and synthesized through sintering, Iwanek’s, PhD, team employs a low-temperature synthesis method. This allows for the production of oxides with a highly developed surface area, ideal for catalytic applications.

Their research has resulted in a granted patent (No. 246995) for an invention titled "Heterogeneous Ruthenium Catalyst, Method of Its Preparation, and Use in Transfer Hydrogenation Reactions". The team demonstrated that ruthenium oxide binds effectively to a solid support made of cerium oxide modified with zirconium ions. These systems show excellent activity in catalytic transfer hydrogenation – a reaction involving the transfer of hydrogen from an inexpensive secondary alcohol (2-pentanol) to acetophenone. Thanks to the high activity of the catalyst, the process occurs under mild conditions, without the need for toxic solvents, hazardous reagents, or compressed hydrogen, and leads to the efficient reduction of acetophenone to 1-phenyl-1-ethanol.

Dr. Iwanek’s innovative approach opens new pathways in catalyst design.

– By carefully selecting the parent oxide and the type and amount of dopant ions, we can not only enhance the properties of existing supports but also give them entirely new functionalities – explains Iwanek, PhD. – This enables us to fine-tune the interaction between the support and the active phase, leading to high activity in transfer hydrogenation and other key industrial reactions – such as carbon monoxide and hydrocarbon combustion, or soot oxidation.

These catalytic processes have broad relevance across modern industry. The combustion of carbon monoxide and hydrocarbons is critical in exhaust gas purification systems, gas turbines, and energy generation. Soot oxidation plays a vital role in diesel particulate filter (DPF) technologies and in industrial systems requiring stringent particulate emission control. Meanwhile, transfer hydrogenation is a valuable process in the chemical and pharmaceutical industries, particularly for the reduction of ketones in alcohol synthesis.